How do 3D printers work?

- Stuart Anderton

- May 16, 2022

- 4 min read

Before we dive into the differences between DLP and LCD, let’s take a brief look at what resin 3D printing actually is, and how both DLP and LCD work.

Resin 3D printing, also known as vat polymerisation, comes in three main flavours: SLA, DLP, and LCD. This article will mainly focus on DLP and LCD, but it’s good to understand how SLA works before trying to understand DLP and LCD.

All vat polymerisation technologies involve a photosensitive resin cured by a light source to produce solid layers and, eventually, whole parts. The resin is contained within a vat, or tank, and is cured against a build platform, which slowly rises out of the tank as the part is formed. The main difference between the three technologies discussed here is the light source.

The most well known and oldest of the three is stereolithography, or SLA. It uses a laser, directed by galvanometers, to cure the resin. Galvanometers can be thought of as mirrors used to guide the laser beam through the transparent tank bottom to a particular point on the build platform.

Instead of a laser, digital light processing (DLP) uses a digital light projector to cure the resin. It flashes images of whole layers onto the bottom of the vat.

Light is selectively directed using a digital micromirror device (DMD), which is a component consisting of hundreds of thousands of tiny mirrors.

Layers generated using DLP printers consist of so-called voxels, the 3D equivalent of pixels. That’s because the projector screen itself consists of pixels.

Less common than the other two technologies, LCD 3D printing is nearly the same as DLP. It also flashes complete layers at the resin tank, but with the UV light coming from an array of LEDs shining through an LCD, not a projector.

A screen acts as a mask, revealing only the pixels necessary for the current layer. As such, no special device is required to direct the light, as is the case in both SLA and DLP.

Now that we’ve covered the three main types of resin 3D printing, let’s focus on the former two, identifying the differences between them.

PRINT QUALITY

DLP projectors and LCD screens exist all around us, in our schools, our offices, and our homes. If you can imagine the differences between the two, you’re already part of the way to understanding the differences between DLP and LCD 3D printing.

DLP

DLP projectors create an image of a layer by shining light through a lens to a DMD, which must then direct the light to the bottom of the resin tank. As such, the light coming from a DLP projector must expand from a small source to cover a wide area. This essentially means wide models have an increased chance of having distorted pixels at their edges.

Furthermore, the number of pixels on a DLP projector is the same regardless of the size of the print. That means smaller and narrower prints can have higher precision than wider prints done on the same DLP printer.

To visualize this effect, think of a photo you’ve taken on your smartphone. As you zoom in on the photo, the sharpness declines. That’s exactly what happens when printing big objects on a DLP printer — they’re “zoomed out”.

That said, it’s important to keep in mind that distortion is corrected for on more professional devices, which have better quality components. Additionally, the “zooming out” issue doesn’t necessarily imply that a DLP printer has poor print quality, only that its resolution is more concentrated for smaller prints.

LCD

LCD 3D printers use an array of UV LCDs as a light source. The light from the flat LCD panels shines directly, in a parallel fashion, onto the build area. Because this light isn’t expanded, pixel distortion is less of an issue with LCD printing.

What this means is that the print quality of an LCD printer depends on its LCD density. The more pixels it has, the better the print quality.

The benefit that both DLP and LCD share, when compared to SLA, is build speed. Because there’s an entire layer is flashed at once, instead of a single point, the two technologies are typically able to produce parts faster.

APPLICATION AND PRICING

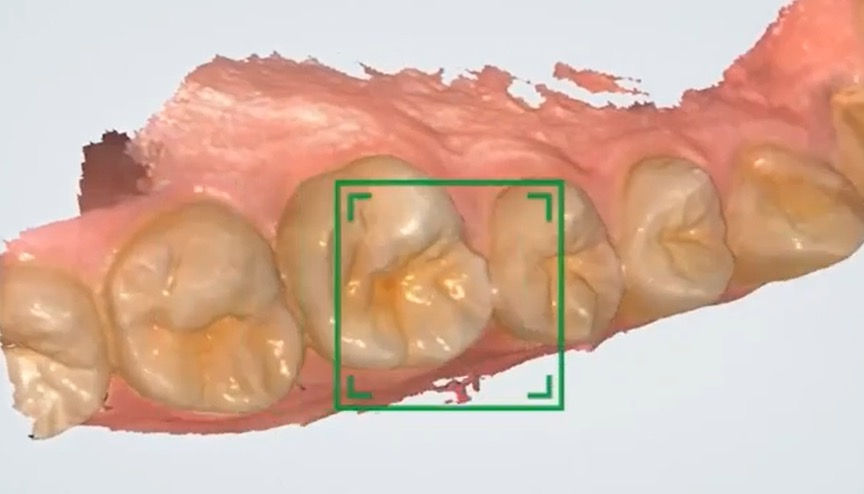

Both DLP and LCD are used in the dental, jewellery and engineering industries, just to mention a few. Naturally, there are also a fair number of hobbyists using both types of printers.

Looking at the market, the general trend is that DLP printers are the more expensive, professional machines. LCD, a more recent technology, has so far been seen mostly in affordable, desktop printers.

As mentioned earlier, cheaper DLP printers sometimes suffer from minor voxel distortion. However, that potential issue becomes less of a problem if one invests a little more money. That’s because, with higher quality printers comes higher quality hardware, which is designed to correct for distortion.

In general, LCD 3D printers use cheaper components than DLP 3D printers, making them a cheaper resin 3D printing solution. This is a great thing because it extends the reach of resin 3D printing to a wider audience of makers.

Both DLP and LCD are able of achieving fast print speeds and great details, but as the price tag grows, the DLP 3D printers start to trump their LCD counterparts.

If you’re a professional who needs high detail and fast print speeds, we’d suggest that you look into professional DLP printers. On the other hand, if you’re a beginner to resin 3D printing, LCD would be a great choice.

Check out the all-new AccuFab range of resin printers from Osseo Group.

The integrated advanced printing software supports intelligent support creation and "one-click" printing, providing a doctor/technician-friendly experience with repeatable consistency and accuracy.

Osseo Group stocks two amazing models and a range of 405nm resins covering a broad range of applications including models, casting, surgical guides and much much more.

DLP Printer AccuFab-D1s HERE

LCD Printer AccuFab-L4D HERE

405nm dental resins HERE

#clearalignerexpert #digitaldentistry #dentistsofinstagram #digitaldentist #intraoralscanner #dentistlife #cosmeticdentistry #smiledesigner #orthodontics #clearaligners #osseogroupanz #3dprinting #printerresin #405nm #shining3d #aoralscan