Crystallise, Glaze, Fire – Programming Your F30 Furnace Made Easy

- Stuart Anderton

- Jul 16, 2025

- 2 min read

The very first step is to read the official user manual below—this will give you the full picture of how your UP3D F30 furnace is designed to operate. Every furnace has its own quirks and interface, so it's always best to understand the manufacturer's guidance before making changes.

That said, we know you're busy and just need to get up and running—so if you're after the quick version, we've put together a practical TL;DR guide. This includes a real example program, step-by-step instructions, and even a deliberate incompatibility that shows how to work around common limitations in the F30 system.

You’ll also find a sensible compromise that lets you keep your workflow efficient without risking the quality of your restorations. It’s designed to help you understand how each value works, where you can be flexible, and what to prioritise when adapting settings for lithium disilicate, zirconia, or PFM workflows.

Start by selecting a program number. For lithium disilicate, use Program 1, as it’s the first step in the LiSi workflow and typically reserved for this material.

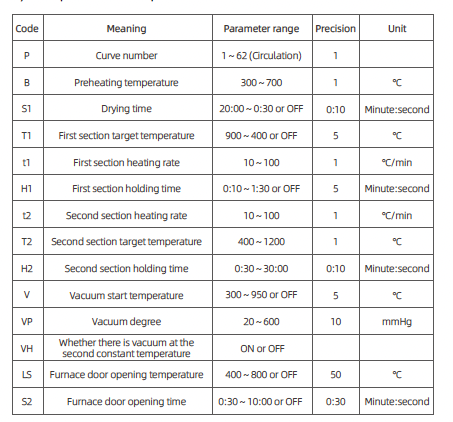

You’ll see the program attributes and curve values—these might look complicated at first, but don’t worry. Here’s a table to help you understand what each value means and the safe limits to work within. You may need to make small compromises to suit your furnace, but minor adjustments won’t affect the final result.

In our example, we’re using lithium disilicate, which follows this firing cycle:

Preheat at 450 °C for 4 minutes

Ramp to 850 °C at 50 °C/min

Hold at 850 °C for 2 minutes

Cool down to 300 °C at 50 °C/min, with the door opening at 300 °C

So, we'll start by setting the following values in our program:

Code | Value |

P | 1 (it can be 1 because it's usually our first step) |

B | 450ºC |

S1 | 4:00 |

T1 | OFF |

t1 | OFF |

H1 | BLANK |

t2 | 50ºC/min |

T2 | 850ºC |

H2 | 2:00 |

V | OFF |

VP | BLANK |

VH | OFF |

LS | 400ºC (the program calls for 300ºC but that's outside our available values) |

S2 | 4:00 (it's not called for but a nice slow opening prevents fractures and is more gentle on the furnace) |

Now you can go on to add more programs. A good tip is to leave gaps of 10 between each material group—this gives you space to add extra programs later without needing to reorganise everything.

For example: Lithium Disilicate

Program 1 – Crystallisation

Program 2 – Add-on

Program 3 – Stain/Glaze

Program 4 – Retouch / Final Glaze

Zirconia

Program 11 – Framework Modifier / Opaquer

Program 12 - Dentine / Enamel

Program 13 - Add-on

Program 14 – Stain / Glaze

PFM

Program 21 – Opaquer

Program 22 - Dentine / Enamel

Program 23 - Add-on

Program 24 – Stain / Glaze

Need help setting up your furnace or choosing the right workflow?

Call your Osseo Group account rep or click HERE to book a demo of our materials and equipment in your clinic.